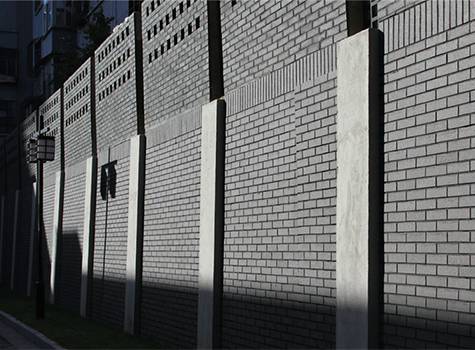

Outdoor Wall Tiles Split tiles

-

Outdoor Wall Tiles Split tiles

ZSR Tiles is a leading ceramic / clay terracotta manufacturer in China, we have the ISO9001, ISO14001, EN CE 14411 etc certificates, and our Fujian Jinjiang Zhongshanrong Ceramic Co., Ltd , which located in Cizao Town , one of five production bases of building ceramic in China, specializing in the development and production of the splitting tile series products for several years.

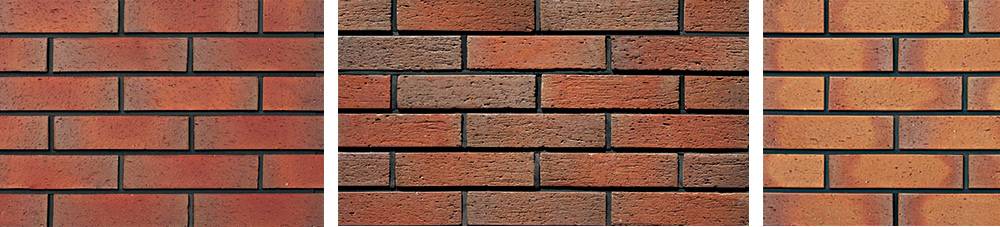

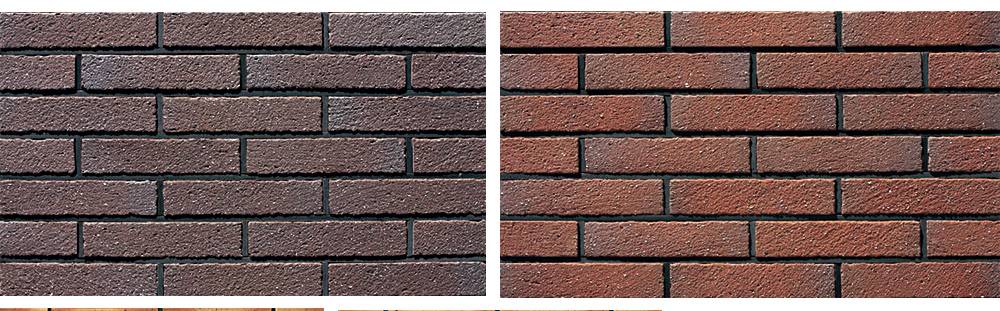

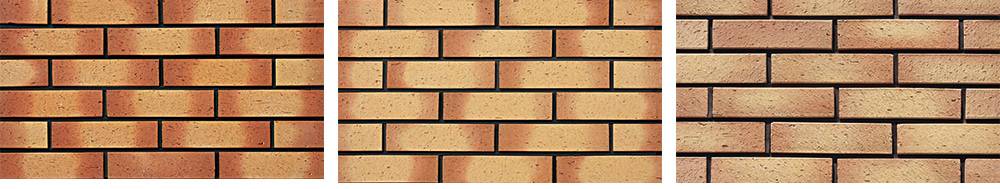

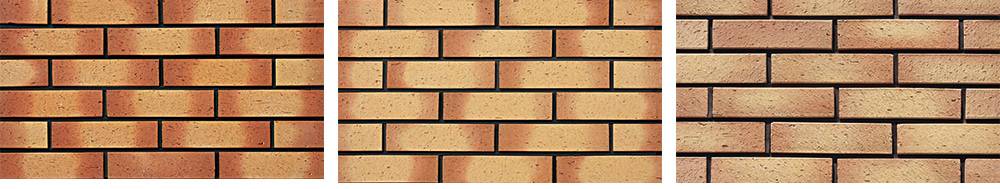

Zhongshanrong split tile is made of selected natural minerals as its raw material ,shaped by vacuum extrusion and treated by the tunnel klin with temperature over 1200℃. Among its similar products,it has the characteristic of better texture,more natural and glossy color and more decent style.It is possessed of not only a natural beauty back to nature,but also strong culture flavor and fashion sense.Decorated with Zhongshanrong split tile, the building can be endowed with artistry and lifestyle with upgrade of its quality and nobility.The creation of a group of boutique buildings and marking projects manifests the quality and value of Zhongshanrong split tile.Our products with unique design of dovetail groove have high binding degree with interface and strong spalling resistance.Each performance index of the products reaches the national standard,such as high folding strength,low water -absorption, dramp proofing,Acid& Alkali resistance,freeze proofing,heat preservation and sound absorption.They can be widely applied to the decorations of many places such as the vertical faces of the internal and external building walls,ground,square,school and villa.With a full range of various specifications, their use value and aesthetic value turn into a unity of perfection.Now our popular size: Available surface: 240*60*11mm

230*52*11mm

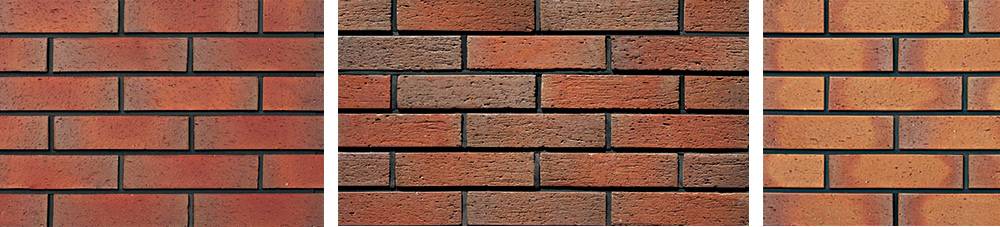

230*52*11mmTurn colors series

Draw crude series

Vertical line series

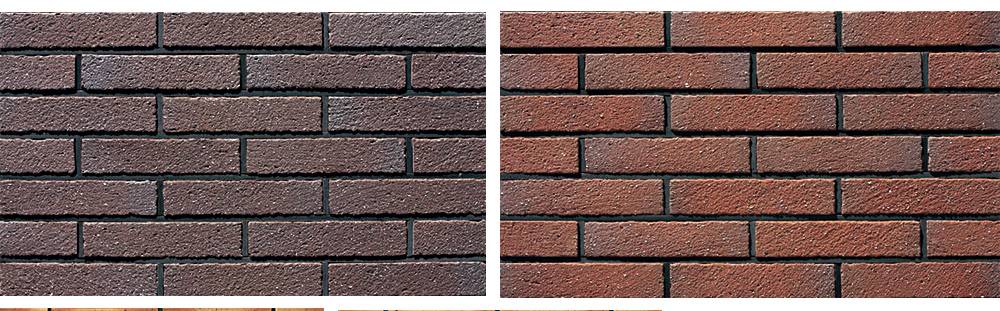

Rub-sand series

Plane series

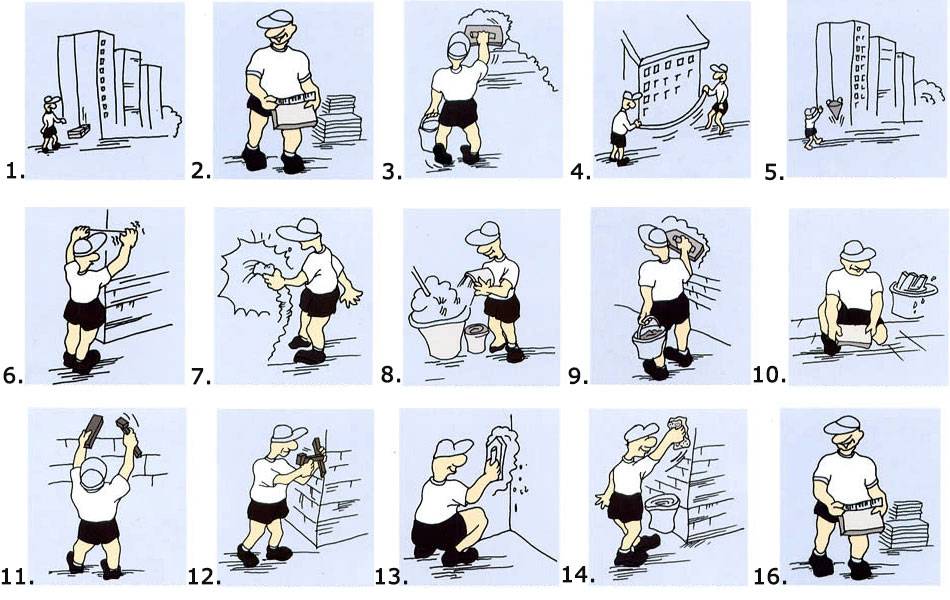

Outdoor wall tiles-split tiles Instructions for wet pasting of split brick

1. Make a good plan according to sizes of tiles; attention should be paid to the dimensions and color numbers marked on the package before use, to ensure uniformity.

2. High-rise buildings require a vertical line with a plumb line to decide quarrying or leveling the wall surface before making marks for renderings on the wall surface according to the tile dimensions.

3. Then cement and sand are mixed on a ratio of 1:3 into cement paste; a wooden trowel is used to render the wall surface and make it completely level.

4. After the cement paste dries on the wall surface, water pipeline is used again along the wall surface to complete the construction plan based on the dimension of tiles, so as to determine the horizontal line (X-axis).

5. A hammer is used to determine the vertical line (Y-axis).

6. Snap ink lines to mark the construction area.

7. Before construction, the wall surface shall be sprayed with water based on the dryness of the weather and of the rendered surface, so as to avoid the adhesives drying too fast and becoming inflexible.

8. Before the adhesive for the external wall is mixed, the tiles or lithology shall be considered, for water absorption will affect the amount of hyperacid powder to be added.

9. On the construction area marked out by snapped ink lines, adhesive is applied evenly on the rendered wall surface, and dentoid sickle is used to make wavy strips on the leveled paste, so that when the tiles are installed, redundant adhesive will be squeezed out to make firmer adhesion.

10. Install the tiles onto the construction wall surface one by one. (Before installation, tiles need to absorb sufficient water)

11. When installation of tiles on unit area is completed, iron ruler and hammer handle are adjusted to adjust the horizontality and verticality.

12. Knock the tiles slightly with hammer handle to make them firmly fixed. For small tiles, it is recommended to knock the overall surface with a plant, so as to make the tile surface level and pretty.

13. If tiles have touched cement adhesion during the construction process, the tiles must be cleaned first.

14. 24 hours after the construction, clearances on the tile surface are filled with adhesion; most filler are of the cement color, or be added with pigment or black clay as might be required by the client.

15. Fill the clearances with sponge trowel and filler first; then the tiles are scoured with the sponge and clean water.

16. Finally, clean water is used with detergent to clean the tiles thoroughly.